Manual

Immunity development system E1

Table of contents

1 Description of the E1 immunity development system

The E1 immunity development system is an advanced tool for the electronics developer to examine the immunity of modules to pulsed interference (burst/ESD) in experiments. The system allows him to analyse the interference immunity in the confined space of a module. The selective injection of disturbance current into individual sections (disturbance current paths) and application of pulsed electric (E fields) or magnetic (H fields) fields to selected areas of the module's surface are decisive for the localisation of weak points. While pulsed disturbances are applied to the device under test, the signals can be monitored simultaneously via optical fibre without interaction.

The E1 immunity development system has been specially designed for the development process. It helps the developer suppress interference in devices/modules or further harden them since it allows him to clarify the immediate causes of immunity problems and test the effects of counter-measures directly.

The E1 immunity development system cannot be used for standard compliance tests. Testing a module's immunity on the basis of the IEC 61000-4-4 and IEC 61000-4-2 standards, however, is an ideal starting point for examining the device under test with the E1. The disturbances generated by the standard burst generator in accordance with the standard are injected into the supply lines of the device under test and flow back to the generator via ground. The paths on which the pulse-shaped disturbances flow through the device module are not known. An unknown percentage of these disturbances encounters an unknown victim in the device and generates a functional fault. This weak point can usually be pinpointed to a few square centimetres of a module but can only be localised with difficulty in a standard compliance test. The developer does not yet know if and where the disturbance current with its associated magnetic field induces a voltage pulse in a conductor loop or couples electric field capacitively to sensitive lines.

Exact information about the fault pattern that has occurred is the decisive result of a failed compliance test. But the fault pattern does not reveal precisely where the weak point of the device under test lies. A test in accordance with the standard should thus initially be performed to determine the immunity of the device under test so as to identify the fault pattern. The developer can then use the E1 at his workplace to analyse the causes of the immunity problems, where the functional faults shown in the fault pattern provide a certain orientation for interference suppression. The immunity development system allows the developer to verify the effectiveness of EMC modifications carried out in the interference suppression process immediately and thus to achieve a significant reduction in the development time and development costs.

2 Description of the E1 components

The E1 immunity development system comprises a SGZ 21 pulse density / burst generator, an S21 optical sensor, an MS 02 magnetic field probe with optical fibre output, magnetic and electric field sources and numerous accessories.

2.1 SGZ 21 pulse density counter / burst generator

The SGZ 21 (Figure 2) is a burst generator with potential-free pulse generation on the one hand, and on the other hand the SGZ 21 is also a pulse density counter to measure the disturbance pulses of the device under test.

Generator ON/OFF: to switch the SGZ 21 on or off

Intensity: potentiometer to gradually adjust the intensity of the disturbance pulses

Pulse shape: toggle switch to change between steep and flat pulses

Counter display: six-digit counter to measure the pulse density

SIGNAL LED display: to indicate the received light signal

SPIKE LED display: to indicate the received light signal with pulse trap; the pulse is stretched to a visible width of 50 ms

Burst output: symmetric output galvanically isolated from ground

Counter's optical fibre input: input socket for 2.2 mm plastic optical fibre

The power supply is located on the left side of the generator. A 12 V power supply unit is included in the scope of delivery.

2.1.1 SGZ 21 as a disturbance generator

The SGZ 21 generates potential-free, pulse-shaped disturbances whose edges have a rise time of approx. 2 ns and a fall time of approx. 10 ns. In contrast, a standard generator generates pulse shapes of 5/50 ns. The SGZ 21's smaller pulse width prevents the device under test from being destroyed. Furthermore, working at a lower disturbance voltage level ensures greater safety for the engineer. The SGZ 21 allows partial injection into structural parts, cables, shielding, earth connections and primarily directly into the modules. The disturbance current of the SGZ 21 is generated via a differential output. Consequently, the generated pulsed current does not relate to the generator housing potential.

The path that the disturbance current takes through the device under test can be defined by contacting the device under test accordingly. Disturbance current can thus be injected into defined sections of the module without significantly influencing the environment.

The peak values of the disturbance pulses are between 0 and 1500 volt. They are constantly changed but are stochastically evenly distributed.

- The SGZ 21 has a symmetric output that is galvanically isolated from ground. The disturbance pulses are coupled out capacitively with alternating polarity.

- The pulse shape toggle switch of the SGZ 21 can be used to change over between steep and flat pulses to adjust the disturbance effect.

2.1.2 SGZ 21 as a pulse density counter

A counter with an optical input (2.2 mm plastic optical fibre) is integrated in the SGZ 21 (Figure 2). A sensor that is located in the device under test (Chapter 2.3) or a magnetic field probe transmits light pulses to the SGZ 21 counter via an optical fibre and the optical input. The received light pulses are initially displayed by the "Signal" and the "Spike" LEDs and then counted by the counter. The counter's peak time is 1 s. Using the pulse density method (Chapter 3) allows a very fast assessment of the sensitivity of a device under test.

The SGZ 21 can be operated standing perpendicular on its rear so that you can easily read the counter from above – e.g. when working standing up.

2.1.3 Preparing the SGZ 21 as a disturbance generator

Generator cables and connecting terminals are needed to operate the SGZ 21 as a disturbance generator. The generator cables are connected to the SGZ 21 output sockets via the 4 mm plug (banana plug). The generator cables (Figure 3) end in two-pole 0.64 mm plug pins. Both pins are connected to the core of the cable. Only one plug pin of each generator cable is used to connect the 250 mm long extension cable (Figure 5).

The connection to the device under test is via alligator clips or micro-kleps (miniature clamp-type test probes with rotating grip jaws) (Figure 4). The field sources contained in the E1 system can be connected directly to the extension cables as required.

2.1.4 Preparing the SGZ 21 as a pulse density counter and for signal monitoring

The optical fibre has to be inserted into the input up to the limit stop and fastened with the knurled screw (Figure 6).

2.2 Field sources

The field sources are supplied with disturbance current from the SGZ 21 and generate either pulsed magnetic or electric fields depending on the type of field source used. The field intensities of these pulsed fields are comparable to those generated by burst currents on the surface of modules during standard compliance tests. The field sources can be used to subject small areas of the device under test or individual conductor runs to defined disturbances.

The field sources contained in the E1 system are optimised so that they generate either a magnetic field or an electric field. Furthermore, the field sources are of different sizes, allowing the developer to apply the pulsed field to differently dimensioned areas on the module. In addition, there are special field sources for specific tasks such as magnetic field sources that couple to conductors via a specially shaped field. Different types of probe heads are offered that are designed for certain measurement tasks. They allow the developer to pinpoint weak points to the millimetre or to search for critical links and connections such as components, conductor runs or IC pins on the defined interference path. The sensitivity of different IC pins can be assessed. Following localisation, the sensitive areas can be treated in a specific way.

E-field-sensitive weak points cannot be identified with H-field sources. Special E-field probes have to be used to localise these weak points. Apart from conductor run sections, high-resistance components such as pull-up resistors or quartz generators may also prove critical in this respect.

2.2.1 Field sources for magnetic fields

The E1 contains four field sources which are able to generate magnetic fields. Thanks to the probe head's various designs, two types of measurements can be performed:

- Determination of an IC pin's / conductor's sensitivity irrespective of whether a layout-related disturbance is conducted to the IC. This measurement provides the developer with an overview of which IC pins and/or conductor runs are sensitive in general.

- Localisation of weak points in the layout. The disturbance fields applied from outside during the standard compliance test couple to the module's conductor runs at weak points in the layout. The disturbances are passed on to the IC via the conductor runs. The disturbance process triggered by the standard compliance test on the module is generally due to electric and magnetic field coupling. The E1 system contains field sources which have been custom-developed to simulate these field coupling phenomena for fault localisation.

| Field pattern | Use | Design |

|---|---|---|

| BS 02 is a field source to localise weak points in the layout. The magnetic field source produces a B-field line bundle with a diameter of > 5 cm. It is suitable for investigations on both devices and modules. The size of the probe allows the developer to apply the field to large areas of housing surfaces and inner spaces, connecting elements and modules with conducting structures as well as ICs to identify weak points that are sensitive to magnetic fields. |  |

| BS 04DB is a field source to localise weak points in the layout. It generates a B-field line bundle in the millimetre range (approx. 3 mm). The field beam emerging from the probe's face can be used to scan the surface of circuit boards and resolve magnetically sensitive weak points in small spaces of 3 mm in the field of layout and packaging. The BS 04DB allows the localisation of critical conductor run sections, components and component connections. |  |

| BS 05D is a field source to localise weak points in the layout. The magnetic field source generates a B-field line bundle with a diameter of approx. 3 mm similar to the BS 04 DB. But the field lines are at an angle of 90° to the probe shaft. The probe is thus ideal to localise weak points between two printed circuit boards or in hard-to-reach locations of modules between components, for example. Before using the BS 05D field probe, the weak point should be roughly narrowed down with the BS 02 or BS 04DB probe. |  |

| BS 05DU is a field source that can be used to determine an individual IC pin's/conductor's sensitivity. The magnetic field source generates a circular magnetic field in the millimetre range. It can also be used as a mini coupling clamp to couple disturbance current into selected individual conductor runs, IC pins, SMD devices and thin lines (ribbon cable). A module often has several insensitive and only a few sensitive signal connections (conductor runs, IC pins). The field source is the ideal tool to quickly identify the sensitive ones and carry out appropriate layout modifications. |  |

2.2.2 Field sources for electric fields

The E1 contains five field sources which are able to generate electric fields. Thanks to the probe head's various designs, two types of measurements can be performed:

- Determination of an IC pin's/conductor's sensitivity

- Localisation of weak points in the layout

The size of the coupling electrode in the probe head is the field sources' distinguishing feature.

| Field pattern | Use | Design |

|---|---|---|

| ES 08D is a probe tip that can be used to determine an individual IC pin's / conductor's sensitivity. A galvanic isolating point with capacitive coupling of approx. 1 pF is contained in the probe tip which is ideal for very small structures. The pin / conductor run is contacted with the probe tip and its sensitivity determined by changing the intensity on the SGZ 21 ("Intensity" controller) in the test. The field source has to be connected via two poles. One conductor is connected to the probe tip via a coupling capacitance of 1 pF. The second conductor is connected to a counter-electrode, preventing disturbance current from flowing through the device under test unintentionally and thus affecting other areas. Connection: two-pole |  |

| ES 05D is a field source that can be used to determine the sensitivity of an IC pin/conductor or individual components. The E-field source has a narrow line-shaped coupling electrode in its probe head. This design makes it ideal for being placed on conductor runs and small components and their connections, wires and individual SMD components such as resistors and capacitors. Individual plug contacts or cores of ribbon cables can also be examined. The probe is placed on the component/conductor run to inject the E-field. Connection: two-pole |  |

| ES 02 is a field source to localise weak points in the layout. The size of the field source allows the developer to couple the field to large areas of housing surfaces and inner spaces, connecting elements and components with conducting structures and ICs (e.g. bus systems, LCD displays). The tip of the E-field source can be used to localise small weak points that are sensitive to E-field (conductor runs, quartz crystal oscillators, pull-up resistors, ICs). Connection: two-pole |  |

| ES 01 is a field source to localise weak points in the layout. The field source allows electric coupling to large areas. The probe is ideal for applying an electric field to extensive or line-shaped weak points with a size of 5 to 10 cm and ranks between the ES 02 and ES 00 field sources (please refer to the corresponding description). The ES 02 may be too small and the ES 00 source too large for certain purposes. The ES 01 can also be used to couple disturbance current to a module. The intensity of the disturbance current can be controlled by the distance between the probe and the module. Connection: single-pole |  |

| ES 00 is a field source to localise weak points in the layout. The field source allows electric coupling to large-area or line-shaped structures (150 cm²). Electrically sensitive weak points often extend over large areas from 10 to 15 cm of a module (LCD display, bus systems). These weak points do not respond to small field sources. Large-area field sources such as the ES 00 are needed to identify this type of weak points. The source can also be used for coupling to housings. The ES 00 can also be used to couple disturbance current to a module. The intensity of the disturbance current can be controlled by the distance between the probe and the module. Connection: single-pole |  |

| Key to designations | |||

|---|---|---|---|

| Example: BS 04DB | |||

| Type of field | Size | Attenuation | Special field shape |

| BS Field source for magnetic field ES Field source for electric field | 00 01 02 | D Common-mode attenuation | B Bundled field lines U Circular field |

2.2.3 Measurement set-up with SGZ 21 to inject burst current with field sources

The field sources are connected directly to the "Burst output" (Figure 2) of the SGZ 21 via the generator and extension cables. Magnetic field sources are always connected via two poles (Figure 7).

Depending on their type, field sources for electric fields are connected via one pole or two poles (Figure 31).

Apart from the field sources themselves, the connecting cables also generate fields that may couple to the device under test and affect the measurement result. Cables should thus always be kept away from the device under test if possible.

2.3 Sensor

The S21 sensor (Figure 8) is a digital probe head to transmit binary signals from the device under test. The sensor has a three-pin shrouded header (RM 2.5 mm). One pin of the shrouded header is the 3.5 V auxiliary power supply. The second pin is the ground pin. The third pin is the input of the probe head. The sensor input is connected internally to a digital IC input. This is connected to digital signals, VCC (≤ 5 V) and ground inside the device under test. The IC output supplies an optical transmitter. The transmitter is connected to a 2 mm conical socket to accommodate a 2.2 mm plastic optical fibre (LWL). The light signals from the sensor are transmitted to the 'LWL' counter input of the SGZ 21 via an optical fibre.

The level changeover switch allows the signal to be negated.

The sensor can be used in two different ways:

- to detect logic signals in the device under test

- to detect disturbances in the device under test

to a) It is helpful if important signals (Reset, CE) of the device under test are monitored so as to find the causes of problems in immunity investigations with the SGZ 21. When using a conventional oscilloscope probe head, the disturbances are led to the oscilloscope via the probe head. The disturbances would affect the oscilloscope. In addition, the probe head would change the disturbance current paths of the device under test and thus falsify the measurement results. This is the reason why probe heads with an optical fibre connection have to be used. The S21 sensor is such a probe head.

to b) The IC input of the S21 sensor has an immunity level that can be used to detect disturbances in the device under test.

Pulse stretching

The S21 sensor of the E1 can detect fast transient disturbances. The pulse widths of these disturbances may be in the nanosecond range. Due to the low limit frequency of the optical system (5 MHz), such short disturbances cannot be transmitted. A pulse stretching circuit which stretches short pulses to 100 ns is integrated in the sensor. The optical fibre is then able to transmit these pulses. Neither can the optical system of the sensor transmit frequencies above 5 MHz. The same sensor circuit reduces frequencies > 5 MHz to 5 MHz.

Without this circuit, the optical system would not be able to transmit anything. It would assume a high or low state. The circuit ensures that fault states are transmitted from the device under test.

2.3.1 Principal mode of operation of the sensor

The sensor is integrated in the device under test and connected to the line of interest. A three-pole socket (included in the scope of delivery) is glued to the device under test with super glue in the immediate vicinity of the interesting signal line, if possible at the input, and wired with a short CuL wire; the ground, 3-5 V voltage and sensor input are also wired before the sensor is connected (Figure 9). The wiring should be short and laid directly on the module's surface so as to prevent the formation of loops where magnetic or electric fields could couple in.

The S21 sensor is supplied with a 3 to 5 volt voltage from the device under test. If this is not possible, a battery module can be used (not included in the scope of delivery).

2.4 Magnetic field probes

The magnetic field probe is used to measure burst-related magnetic fields in the device under test. The disturbance current i of the SGZ 21 generates a magnetic field B. The magnetic field which penetrates the probe head induces a voltage in the probe head's induction coil. The voltage drives an optical transmitter diode that is located in the MS 02 probe shaft (Figure 10).

Each disturbance pulse of the SGZ 21 causes a light pulse of the optical transmitter diode. The transmitter diode has a 2.2 mm conical socket and is integrated in the MS 02 probe shaft. An optical fibre is guided from the rear end of the MS 02 probe shaft through to the socket of the transmitter diode. The light pulse is transmitted to the SGZ 21 in the same way as with the S21 sensor (Chapter 2.3). The measurement of the magnetic field is based on the pulse density method (Chapter 3).

Fields which penetrate the probe's induction coil in the orthogonal direction induce a voltage. Fields whose direction coincides with the coil plane do not induce a voltage and are thus not detected. The maximum voltage corresponds to the direction of the magnetic field (Figure 11). The MS 02 magnetic field probe is used to determine the field distribution. The probe emits a light pulse for each magnetic field pulse which is detected. The value shown on the SGZ 21 counter is proportional to the mean magnetic field strength measured (Chapter 3, pulse density method). The field line configuration and field density are indicative of the disturbance current distribution in the device under test.

The MS 02 is a passive probe and does not require any auxiliary power. The power needed to generate the light pulses is taken from the burst-related magnetic field. The MS 02 is connected to the SGZ 21 counter input via an optical fibre.

3 The pulse density method

The pulse density method is a measuring method which can be used to determine the relative immunity of a device under test. The effect of EMC modifications can be evaluated based on the relative immunity. Furthermore, the pulse density method is the basis for measuring burst-related magnetic fields with MS 02 magnetic field probes and the optional S2 magnetic field measuring system (Chapter 10).

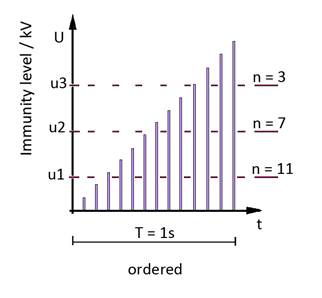

Figure 12 shows how the pulse density method functions in principal. The voltage u of the disturbance pulses gradually rises from a minimum value to a maximum value up a ramp over the time T = 1 s. This process is continuously repeated.

If the disturbance pulses encounter an immunity level u1 in the device under test, the disturbance pulses which are greater than u1 will exceed the immunity level u1. This is n = 11 pulses in the example. If the device under test has a higher immunity level, u3, for example, n = 3 pulses will exceed the immunity level. The number of pulses which exceed the immunity level is inversely proportional to the value of the immunity level.

This principle can be implemented with the E1 components, i.e. the SGZ 21 and the S21 sensor or the MS 02 magnetic field probe. The SGZ 21 generates disturbance pulses which are injected into the device under test. The S21 sensor is used to create an immunity level in the device under test. If the immunity level of the S21 sensor is exceeded, a light pulse is transmitted to the SGZ 21 counter via optical fibre. The counter counts how often the immunity level is exceeded. Depending on the immunity level, the value in the aforementioned example is: n = 3, n = 7, n = 11. These values are proportional to the immunity of the device under test relative to the immunity level of the sensor.

This means: the immunity of the device under test is high at n = 3 and the immunity of the device under test is low at n = 11.

The pulses that are counted in practice may be in the range between 0 and 3,000. A low value is indicative of a high immunity while a higher value is indicative of a low immunity.

There are two possibilities of creating an immunity level with the S21 sensor in the circuitry of a device under test.

Figure 13 shows the simulation of a signal conductor run with enamelled copper wire. The enamelled copper wire is connected to ground on one side and to the input of the S21 sensor on the other. The SGZ 21 is connected to the device under test via two poles. The disturbance pulses iStör from the SGZ 21 penetrate the device under test and generate a burst-related magnetic field B. The burst-related magnetic field induces a disturbance voltage in the inserted enamelled copper wire loop which becomes effective on the S21 sensor input. A light pulse is triggered when the immunity level of S21 is exceeded.

Figure 14 shows the simulation of a signal conductor run with enamelled copper wire. The enamelled copper wire is connected to a pull-up resistor on one side and to the S21 sensor input on the other. The SGZ 21 is connected to the device under test via one pole. An electric field is generated at the surface of the device under test. The electric field couples capacitively to the enamelled copper wire and generates a disturbance voltage on the S21 sensor input. A light pulse is triggered when the immunity level of S21 is exceeded.

An original conductor run of the device under test is used for the same process in Figure 15. The pulse density method can be used with the set-up shown in Figure 13 if high-frequency signal sequences pass through this signal line.

In the SGZ 21, the pulse sequence is not ordered as a ramp according to the amplitude as shown in Figure 12; rather the amplitude u of the pulse sequence is distributed stochastically.

The generator and counter do not have to be synchronised. The start time does not affect the result. The number of pulses measured depends on both the device under test and the "Intensity" controller setting. The system works at its optimum if the greatest number of pulses does not exceed the value 2,000. The intensity should be reduced if necessary.

4 Prerequisites for interference suppression in a device under test

The immunity values and fault patterns which occurred when the device under test was subjected to disturbances in a standard compliance test are a good basis for working with the E1. The E1 immunity development system can now be used to clarify where exactly the weak points associated with these faults are in the device under test. Appropriate counter-measures can be selectively integrated and their effectiveness tested with the E1.

When working with the E1, the developer simulates the coupling paths from the standard compliance test and runs a targeted search for the respective fault patterns from the test. Please note that the E1 can be used for coupling at such high intensities that fault patterns become visible which did not occur in the standard compliance test and which the developer should not try to trace at this time. The developer must always compare the fault patterns triggered with the E1 to the fault patterns that occurred in the standard compliance test to stay on track. Passing the standard compliance test is the key objective. In addition, the developer can use the E1 to further harden the product.

The following issues should be clarified:

- Which malfunction occurs as of which voltage?

- Does the malfunction occur immediately or only after a certain time (statistics)?

- Is the fault exactly the same in each measurement or are there any differences?

- Which differences result from modifying the cable position, for example?

- Do other faults occur less frequently, for example, along with the known malfunctions?

After this initial analysis of malfunctions, the developer should try to find a logical explanation for how the faults occur. This malfunction theory should run as a common thread through all subsequent work. The developer should check and adjust this theory continuously during the entire measurement process. The process aims at finding a relationship between a certain coupling path and the traced malfunction. The developer should then narrow down the fault using the E1 measurement technology. The type of malfunction caused and the required disturbance intensity are always the decisive criteria for a coupling path's degree of relevance.

The key factor for successful measurements with the E1 is that the developer concentrates on following the common thread of testing on the basis of fault patterns.

5 Measurement strategies for interference suppression in a device under test

Disturbance currents flow through the modules of a device under test during a burst test (Figure 17). The major share of the disturbance current flows via the low-impedance supply system.

There are two basic principles of interference:

1. Disturbances via magnetic field – two-pole connection to the device under test using the SGZ 21 (Figure 17)

If the disturbance current enters the device under test (printed circuit board) via a conductor during a burst test and also leaves the device under test via a conductor, a disturbance current flows in a closed circuit from the generator and back to this via the device under test (printed circuit board). The disturbance current generates magnetic fields on the printed circuit board.

These fields produce voltage differences in the ground system of the device under test (printed circuit board) and/or induce voltages in signal line loops. Such voltages in signal line loops can be induced on the circuit board or in connecting systems between the circuit boards.

2. Disturbances via electric field – single-pole connection to the device under test using the SGZ 21

If the disturbance current enters the device under test (printed circuit board) via a conductor during a burst test and leaves it capacitively via an electric field, an electric disturbance field is generated on the surface of the printed circuit board. An electric field is also generated at galvanic isolating points in the device under test.

This process results in disturbance voltages between the modules and structural parts or relative to the ground plane in the device under test. Due to the differential voltage between the module and the surrounding metallic parts, electric fields are generated at the surface of the printed circuit board. These fields couple to conductor runs, pins and components and may interfere with the connected ICs.

The different tools included with the E1 allow four measurement strategies to clarify even the most complex of EMC immunity faults:

5.1 Analysis of the interference current paths; injection directly into the printed circuit board with the SGZ 21 generator

5.2 Localisation of weak points in the layout and components using field sources

5.3 Monitoring of critical logic signals of the printed circuit board

5.4 Measurement of the burst-related magnetic fields to trace the disturbance current

The faults are narrowed down in systematic steps. The first step is always the analysis of the interference current paths and a reproduction of the fault patterns from the standard compliance test. Different measurement strategies (5.2 to 5.4) can be applied depending on the behaviour of the device under test and the developer's own theory about this behaviour.

5.1 Analysis of the interference current paths

The disturbance current i is injected via the mains connecting cable, for example, in the standard compliance test. The disturbance current spreads across the modules and structural parts in the device. Electric and magnetic disturbance fields are produced. These fields may encounter weak points at any place and trigger malfunctions. But the exact location of the weak point cannot be identified (Figure 17).

The E1 can be used to inject disturbance current into individual paths at random (Figure 19). The malfunction is triggered if an electric or magnetic field, which is generated by this, encounters the weak point. Hence, the fault location is narrowed down. Fault localisation begins as soon as a malfunction is triggered in the device under test. Individual sections of the device under test such as individual modules, individual cable connections, small areas of a large module, etc. are initially investigated.

5.1.1 Basic principle of magnetic coupling – two-pole injection into the device under test

The objective of the first step is to reproduce the fault patterns from the standard compliance test. The first test is thus performed with the device completely set up. The device under test is contacted with the SGZ 21 in accessible places and a disturbance current is injected. This is demonstrated by way of an example in Figure 19. One pole of the SGZ 21 is connected to the terminal of the auxiliary power supply. The other pole is connected to the housing (PE). The interference current path closes to the housing via supply conductor runs, discharge capacitors and discharge paths. The magnetic fields of the burst current penetrate the upper printed circuit board and interfere with the processor system. A clever choice of injection paths marked red in Figure 19 allows the developer to draw conclusions about the approximate location of the actual interference and its mechanism of action.

If the disturbance current flows through the device under test via conductors or large capacitances (in the nF range), it encounters a constantly low-resistance path in the area of the device under test. This requires disturbance currents with a high intensity and corresponding strong magnetic fields. Only small electric fields have to be expected in this case.

The occurrence of the sought-after malfunction in this situation suggests magnetic interference. In the case of devices under test with several printed circuit boards or with large modules it is helpful to guide the disturbance current through only individual printed circuit boards or sections of the module and thus narrow down the sensitive area.

This requires different variants of coupling disturbance current to the device under test, such as:

- Disturbance current can be fed through sections of the ground system if the two generator outputs are galvanically connected to the ground system of the device under test.

- Disturbance current can be fed to ground and returned via VCC.

Disturbance current can be fed into the primary side of a transformer or opto-coupler and returned via the secondary side. (Take appropriate protective measures when working with voltages of more than 42 V!)

Both generator outputs are connected to the device under test for two-pole coupling.

Figure 19 shows that not all of the coupling paths marked red are accessible in the device if set up completely. The housing prevents the SGZ 21 from being connected to the printed circuit boards.

The SGZ 21 can only be connected to metal parts (PE bolt) of the housing and lines that lead to the outside (Figure 20).

Since the SGZ 21 has to be connected directly to the printed circuit boards, the housing must be removed as far as possible (Figure 21).

The areas between the printed circuit boards are hard to reach in the device under test. The printed circuit boards may therefore have to be removed from the device and arranged with their original connections alongside each other. The printed circuit boards can be unfolded directly and are then easily accessible if they are flexibly connected in the device under test. If, however, they are firmly connected by pin shrouded headers, for example, they can only be unfolded with additional adapters (Figure 22).

The printed circuit boards of the device under test are now fully accessible and disturbance current can be selectively coupled to them via a two-pole connection.

Possiblities of injecting:

- via the incoming supply to printed circuit board 1

- via printed circuit board 1

- via the plug-in connector between printed circuit boards 1 and 2

- via printed circuit board 2

- via the incoming supplies to printed circuit board 2

The generator is switched directly to the lines of control and supply lines. The generator pole is connected to the line shielding of data lines. The second pole closes the generator circuit to ground of the printed circuit board (Figure 23).

Figure 23 The generator is connected directly to control and auxiliary power lines. With data lines, the generator pole is connected to the line shielding or a capacitor coating.

If the disturbance current is injected via a printed circuit board, the generator poles are connected to the board's ground at existing ground points such as terminals, component connections, etc. (Figure 24). If the printed circuit board has a galvanic isolating point, this can be used for injection (Figure 24).

| Figure 24 Injection of disturbance current into the device under test via a two-pole connection and a galvanic isolating point |

| Figure 25 Injection of disturbance current into the device under test via a two-pole galvanic connection to ground |

| Figure 26 Injection of disturbance current via a two-pole connection and the connector of two modules. Contact is made to ground of each of the modules. |

Contact pins can be soldered to the printed circuit board if no suitable points are available in the device under test to connect the generator (Figure 28).

5.1.2 Basic principle of electric coupling – single-pole injection into the device under test

The disturbance current couples to the module via the cable and leaves the module by capacitive coupling via the electric field in devices which have only one cable connection or where all of the connected cables are joined in a cable bundle (e.g. within a cable duct).

Two-pole coupling stands for a closed disturbance current path and conductive coupling. In contrast, single-pole coupling is not consistently conductive. The disturbance current path is closed by a displacement current in this case.

In practice, there are two cases:

- The electric field couples out to a wide area in the environment. The entire device is thereby subjected to the electric field.

- Metal parts (other modules, heat sinks, structural metal parts, etc.) are present in the vicinity of the printed board. Due to their proximity to the printed circuit board, the electric field concentrates on this discharge path. As a result, the field intensity rises substantially. The module is subjected to a higher local load.

Test set-up for case 1:

The disturbance current from the generator enters the device under test by conductive coupling via the connected cable and leaves it to the environment by capacitive coupling. The generator cable can be connected directly to the device under test via the ground system of the circuit board, a cable shielding or, if there is no cable shielding, via a capacitance coating made of copper foil.

In the example ( Figure 29 ), the disturbance current is coupled from the generator to the ribbon cable via a metallic capacitance coating. It flows through the device under test and returns to the generator's counter pole by capacitive coupling. The capacitance coating is made of adhesive copper tape. It is wrapped around a certain section of the ribbon cable. The disturbance current couples from the device under test to the generator cable via an air gap of several centimeters and returns to the SGZ 21. The electric field intensity can be controlled by altering the distance of the generator cable, on the right in the figure, to the module.

Example for case 1:

Structural metal parts, shielding, metal housings, etc. are located directly alongside the electronic module in the device under test. Disturbance voltage differences may occur between the metal parts and the ground system if these parts are not solidly connected to the ground system of the electronics ( Figure 30 ).

The disturbance voltage differences generate electric fields which act on the surface of the module. High-resistance networks with pull-up or pull-down resistors in the range of 1 – 10 kΩ are especially sensitive to these electric fields. The connections of quartz crystal circuits, reset or all pull-up/pull-down arrangements are some practical examples.

Test set-up for case 2:

Attention: Moving your hand or metallic objects towards the measurement set-up will influence the measurement result!

The E-field source (ES 00 to ES 02) connected to the SGZ 21 is used to simulate the neighbouring metal system which generates the electric field ( Figure 31 ). The size of the E-field source can be selected based on the size of the real metal part.

The field source is connected to the second generator pole. Two different coupling mechanisms are conceivable if these tests cause malfunctions:

- The electric field between the device under test and the probe triggers the malfunction directly or

- the displacement current of the electric field flows through the module and generates magnetic fields there which in turn couple to signal line loops and cause a malfunction.

Proceed as follows to distinguish between these two coupling mechanisms:

A short, low-resistance connection is established between the ground system of the device under test and neighbouring metal parts. The voltage difference between the two parts is thereby short-circuited and the electric field no longer exists. If the known malfunction does not reappear, it was caused by the electric field. If it still occurs or is even worse, magnetic interference caused by the displacement current on the module is responsible for this malfunction. In addition, other malfunctions may occur under these conditions.

5.2 Localisation of weak points with field sources

It is not the disturbance current or disturbance voltage that is directly responsible for interference but the electric or magnetic fields caused by them. Magnetic fields are usually responsible for malfunctions that occur under the influence of burst whereas electric fields are responsible for malfunctions that occur during ESD coupling.

The results of the measurements carried out in "5.1 Analysis of the interference current paths" determine which type of field source should be selected for localisation. The respective type of coupling, i.e. single-pole or two-pole, is already indicative in terms of the differentiation between an electric and magnetic field.

Depending on their type, field sources generate a small-scale magnetic or electric field. These fields are systematically coupled to the module to pinpoint the place of interference.

The interference is due to magnetic fields if the malfunction occurs during two-pole injection into the device under test. In this case, magnetic field sources have to be used in the subsequent localisation process.

The interference will be due to electric fields if the malfunction occurs during single-pole injection into the device under test. In this case, electric field sources have to be used in the subsequent localisation process.

This correlation should be used as an indication. Of course, combinations of both mechanisms can also occur in practice. If so, both types of field sources have to be used one after the other.

5.2.1 Mechanism of action behind magnetic field coupling

Magnetic disturbance fields couple to line networks outside the IC. Together with the IC pins, the networks outside the IC form loops in which a voltage is induced. Interference with the IC is via the IC pins and conductors.

| Eqn 01 |

In the simplest and most frequent case, the loops close outside the IC via capacitors ( Figure 32 ).

The magnetic field H(t) generates the magnetic flux density B(t) or the magnetic flux φ(t). The flux φ(t) induces voltage pulses in the conductor loops. The magnetic field enclosed by the conductor loop is responsible for voltage induction. The values of voltages induced in practice are around 10 volt. The impedance of a corresponding conductor loop is in the 1 ohm range. In the process of interference suppression with field sources, the magnetic field is generated by the field source. In order to trigger interference, the field source must be held so that the magnetic field penetrates the conductor loop (Figure 33). The IC starts malfunctioning if the induced voltage is high enough.

5.2.2 Mechanism of action behind electric field coupling

Electric disturbance fields couple to line networks. The line networks form the coupling electrodes to which the current pulse is capacitively coupled via the electric field. In the simplest and most frequent case, these are conductor runs that have high-resistance current paths on the printed circuit board ( Figure 34 ). Line networks with high internal resistances are especially sensitive to electric disturbance fields. These may be pull-up or pull-down circuits with resistances in the kΩ range.

The coupling electrode formed by the conductor run has an outer capacitance per unit length which is the total capacitance CP. This capacitance absorbs a displacement current i(t) from the electric field and feeds this to the conductor run.

| Eqn 02 |

Part of the displacement current is led to the IC. It flows into the IC via protection diodes. The currents coupled in are around 1 A in practice.

The conductor run's capacitance per unit length adds up to the coupling capacitance CP. This capacitance is around a few femtofarad in practice. The interference depends on du/dt of the generator voltage. The steep leading edge of the generator voltage characteristic has the greatest effect.

5.2.3 Practical procedure for coupling with magnetic field sources

The field source is used to search for sensitive conductor loops which are responsible for a certain fault pattern. A disturbance voltage can only be induced in a large conductor loop with field sources that can generate a field beam of a similar size. The BS 02 field source, for example, can be used for conductor loops in the 10 cm range (Figure 36) (2.2.1 Field sources for magnetic field).

Smaller magnetic field sources are required for smaller areas in the mm range. The BS 05DU magnetic field source, for example, is used for IC pins (Figure 37).

The magnetic field source with its field beam is guided directly across the module's surface for magnetic coupling ( Figure 38 ). Only small surface areas are usually sensitive to magnetic fields. The field source has to be swivelled and turned to find these sensitive conductor loops with the field beam. Malfunctions are triggered as soon as a sensitive conductor loop has been found. Selected EMC measures can then be taken at this spot.

| BS 04DB magnetic field source | Use |

|---|---|

| BS 04DB couples a magnetic field to the supply line. The probe is placed directly to the left of the supply line. The magnetic field encircles the supply line in the circuit board. |

| BS 04DB couples a magnetic field to signal lines. It is used to find out whether one of the affected signal lines is sensitive to magnetic fields. The BS 05DU magnetic field probe can then be used for a more precise selection of individual lines. |

| BS 04DB couples a magnetic field to ground between two signal lines. It is used to find out whether one of the two lines is sensitive to magnetic fields. The sensitivity of the lines can only be determined if the lines are sufficiently spaced as shown in the figure. |

| BS 04DB couples a magnetic field between a connector's shielding connection and signal lines (pig tale) to find out whether the signal input is sensitive to disturbances. |

| BS 05DU magnetic field source | Use |

|---|---|

| BS 05DU couples a magnetic field around an SMD capacitor. A voltage is induced in the capacitor to test whether the induced voltage causes malfunctions. |

| BS 05DU couples a magnetic field to a selected conductor run to test whether the induced voltages cause malfunctions. |

| BS 05DU couples a magnetic field to an IC pin to test whether the induced voltages cause malfunctions. Each pin can be tested individually. This allows the developer to compare the individual pins in terms of their immunity. The most sensitive pins can be identified. (The exact immunity levels can be determined with the IC test system: www.langer-emv.de) |

| BS 05D magnetic field source | Use |

|---|---|

| BS 05D couples a magnetic field to the pin of a wired back-up capacitor to test whether the Vdd pin of an IC is sensitive to magnetic fields. |

BS 02 magnetic field source

| BS 02 magnetic field source | Use |

|---|---|

| BS 02 couples a magnetic field to large areas of a module to test whether the star-wired ground system has large-scale weak points. |

| BS 02 couples a magnetic field to a U-shaped ground system to test whether the field affects lines located outside the ground system. |

| BS 02 couples a magnetic field to a ribbon cable to test whether individual lines are sensitive to magnetic field. |

| BS 02 couples a magnetic field to a ribbon cable to test whether individual lines are sensitive to magnetic field. |

| BS 02 magnetic field source | Use |

|---|---|

| BS 02 couples a magnetic field between a connector's shielding connection and signal lines (pig tale) to find out whether the signal input is sensitive to disturbances. |

Please refer to Chapter 2.2 for tips on how to select the individual probes.

The field intensity of a magnetic field source can be adjusted at the SGZ 21's "Intensity" controller (Figure 2). If the intensity is set very high, the magnetic field of the field source spreads over a larger area of the module than if the intensity is set to a lower value. The measurement process has to be adjusted with the "Intensity" controller to exactly pinpoint small sensitive weak points. Even very small sensitive points can then be precisely localised. Should this adjustment prove insufficient, the PULSE SHAPE toggle switch (Figure 2) can be changed over to "wide pulse" so as to attenuate the interference effect. The intensity may then have to be slightly increased again if necessary.

5.2.4 Practical procedure for coupling with electric field sources

The field source is used to search for sensitive conductors or components which are responsible for a certain fault pattern. Coupling to large line sections or line bundles is only possible with field sources which generate fields of a similar size. The field sources ES 00 to ES 02 (Figure 39) (2.2.2 Field sources for electric field), for example, can be used for lines in the 10 cm range. The field source is gradually moved towards the device under test starting at a distance of approximately 10 cm until it rests on the device under test.

Smaller electric field sources are used for smaller areas in the mm range. The ES 05D field source or ES 08D probe tip ( Figure 40 ) is used for IC pins, for example.

The electric field source with its field is guided directly across the module's surface for electric coupling (Figure 41). Only small surface areas are usually sensitive to magnetic fields. The field source is gradually moved towards the sensitive area on the module. Malfunctions are triggered as soon as a sensitive area has been found. Selected EMC measures can then be taken at this spot.

| ES 00 - 02 E-field sources | Use |

|---|---|

| ES 00 couples an electric field to signal lines of a printed circuit board to test the sensitivity of components or signal lines. The ES 05D E-field source or ES 08D probe tip can then be used to select individual lines or components. |

| ES 01 couples an electric field to signal lines of a ribbon cable to find out whether one of the affected signal lines is sensitive to electric fields. The ES 05D electric field probe is then used for a more precise selection of the individual lines. |

| ES 02 couples an electric field to the ground system of a printed circuit board. A disturbance current is coupled capacitively to the printed circuit board. The disturbance current may then affect weak points that are sensitive to magnetic fields. |

| ES 02 couples an electric field to a conductor run. Placing the probe onto the conductor run on edge facilitates the selection of an individual conductor run. This method is ideal for relatively insensitive lines since the E-field source has a longer edge (coupling surface) than the ES 05D. |

| ES 02 E-field source | Use |

|---|---|

| ES 02 couples an electric field to the housing of an IC. The tip of the E-field source is placed onto the IC housing to examine individual areas. This method can also be used for other components (SMD resistors) or conductor runs. |

| ES 05D E-field source | Use |

| ES 05D couples an electric field to the conductor runs of a printed circuit board. If the conductor runs are very close to each other in a bundle, it may not be possible to find out exactly which conductor run is the sensitive one. The developer thus has to find a point in the layout where the conductor run is exposed or he has to use the ES 08D probe tip. |

| ES 05D couples an electric field to a quartz crystal oscillator housing to test the sensitivity of the associated IC connections. Depending on the IC manufacturer, the quartz crystal oscillator connections of ICs can be very sensitive to electric field. |

| ES 05D couples an electric field to the core of a ribbon cable to test its sensitivity. |

| ES 05D E-field source | Use |

|---|---|

| ES 05D couples an electric field to an SMD resistor to test the sensitivity of the associated line network and IC inputs. Pull-up or pull-down resistors usually pose a high risk and should thus always be tested. |

| ES 05D couples an electric field to the housing of an IC to test the IC's E-field sensitivity. Depending on the manufacturer, ICs may be very sensitive to electric fields. The IC's oscillator cells and PLL cells are usually E-field sensitive. |

| ES 08D E-field sources | Use |

| ES 08D couples an electric field to a conductor run to investigate whether a malfunction occurs in the associated IC. |

| ES 08D injects a disturbance current into individual IC pins. Thanks to the needle-shaped tip the desired pin can be exactly selected to test whether the IC pin can be affected by capacitive disturbance current. The individual IC pins can be compared and evaluated. (The exact immunity levels can be determined with the IC test system: www.langer-emv.com) |

Please refer to Chapter 2.2 for tips on how to select the individual probes.

The field intensity of an electric field source can be adjusted at the SGZ 21's "Intensity" controller (Figure 2). If the intensity is set very high, the electric field of the field source spreads over a larger area of the module than if the intensity is set to a lower value. The measurement process has to be adjusted with the "Intensity" controller to exactly pinpoint small sensitive weak points. Even very small sensitive points can then be precisely localised. Should this adjustment prove insufficient, the PULSE SHAPE toggle switch (Figure 2) can be changed over to "wide pulse" so as to attenuate the interference effect. The intensity may then have to be slightly increased again if necessary.

5.3 Monitoring of logic signals from the device under test

The device under test usually provides information about malfunctions during a test. Malfunctions may not be sufficient to assess internal interference processes. Characteristic logic signals from the module have to be monitored to obtain more information about the device under test, such as reset, chip select, watchdog or any other life signs. The E1 offers the possibility of indicating signal states on the SGZ 21 via the Spike and Signal LEDs and counting them with a counter (Figure 2), using an optical probe head, the S21 sensor (Chapter 2.3 Sensor) and optical fibre.

Furthermore, the pulse density method (Chapter 3) can be used to monitor whether immunity levels are exceeded in the device under test.

Figure 42 shows the test-set-up for monitoring logic signals of the device under test. The SGZ 21 generator outputs are connected to the module. A single-pole or two-connection can be used for the set-up. The S21 sensor is connected to the signal that is to be monitored via an adapter socket and enamelled copper wire. The sensor output is connected to the SGZ 21's "counter input" via an optical fibre (Figure 2).

The adapter socket is stuck to a suitable location on the printed circuit board with super glue (Figure 43). 3 V to 5 V supply power, ground and signal are wired to the adapter socket connections in accordance with the sensor assignment (Figure 8). Power can be tapped from a back-up capacitor. The S21 sensor may have to be shielded if a sensitive signal has to be monitored.

5.3.1 Use of the pulse density method to evaluate immunity levels

The S21 sensor input has a defined immunity level. The sensor is connected to a line in the device under test. This creates an artificial device immunity level which, if exceeded, is signalled directly via an optical fibre.

The line in the device under test may be an original conductor run or an artificial signal line made of wire which has been inserted for this purpose (Chapter 3). If an original conductor run is used, no signal or a signal with a constant frequency should be assigned to this conductor run. This is necessary so as to be able to distinguish a signal caused by the immunity level overshoot from the useful signal.

The artificial immunity level allows the developer to evaluate EMC measures which have been taken on filters, housings or the mechanical structure. Changing the discharge paths in the mechanical structure, for example, enables the developer to determine the effect of this measure on the entire device's immunity.

Dimensioning of filters is a typical use of the pulse density method (Figure 44):

The SGZ 21 is used to inject a disturbance current into the device under test. The S21 sensor establishes the device's immunity level with a line of the device under test and transmits a signal to the SGZ 21's "counter input" via an optical fibre each time the level is exceeded. A high value indicates a sensitive line which is sensitive to disturbances.

The effect of filter improvements Figure 44 on the device immunity can be tested immediately. A constant measurement and modification process will lead to the optimum filter design.

5.3.2 Monitoring of logic signals from the device under test

Two strategies can be implemented:

- Constant signals (reset) are monitored which change if a fault occurs. The change is transmitted to the SGZ 21 via an optical fibre and indicated by the Signal and Spike LEDs. The Spike LED has a pulse trap which stretches even very short, optically invisible signals to a signal length that can be perceived by humans (55 ms).

- The S21 sensor monitors sequence cycles (CE) which provide a constant numerical value on the counter. The numerical value changes if the cycle is disturbed due to malfunctions.

During immunity measurements it is crucial that faults which occur in the device under test are detected as quickly and clearly as possible. But interference is often not visible from outside, or only after a longer period time. The processor in the device under test may already have crashed while the LCD module still displays the correct data, for example. This crash would have been recognised immediately if the reset signal had been monitored.

Data traffic on bus systems and/or at interfaces often provides information on the operating state of the device under test. A precise analysis of the data with an oscilloscope or logic analyser is usually too time-consuming and costly. A quick alternative is to monitor the data stream with the SGZ 21 counter. Of course, due to changing data contents and a lack of synchronisation between the counter and data packages, a constant numerical value cannot always be obtained on the counter. But certain numerical values are usually assigned to certain operating states. The developer will thus recognise certain successive numerical values when the system starts up after a RESET, for example, from which he can draw conclusions about the respective current operating state of the device under test.

He can see whether interference is responsible for a system restart or the unusually frequent retransmission of data, for example, during immunity measurements.

The optical OSE systems allow a more precise examination of the processes in the device under test during burst measurements. The signals of the optical sensor are transmitted to an oscilloscope via an optical fibre. The signals of the device under test can be traced exactly with the oscilloscope. An optical receiver of the OSE system converts the light signals into electric signals (www.langer-emv.de).

5.4 Measurement of burst-related magnetic fields

It is good to know the distribution of burst-related magnetic fields so as to understand the interference mechanisms in the device under test. The MS 02 magnetic field probe can be used to measure burst-related magnetic fields in the device under test. The magnetic field probe is galvanically isolated by an optical fibre to prevent interaction with the device under test. The optical fibre is connected to the SGZ 21's counter. The signals of the magnetic field probe are evaluated on the basis of the pulse density method. The counter displays a number which is proportional to the measured magnetic field.

The measurement of burst-related magnetic fields allows the developer to answer crucial questions such as:

- Where do magnetic fields exist in the device under test?

- Which path does the disturbance current take in the device under test?

- Does disturbance current enter the IC via inputs and outputs?

- How effective are the integrated discharge capacitors and how big should they be?

- How does the length of a shield connection affect the discharged current?

- etc.

Measurements with the MS 02 magnetic field probe provide two results: the absolute value of the magnetic field (pulse count) and the direction of the magnetic field (position of the probe head) (Figure 10 and Figure 11). This gives the developer a clear idea of the magnetic fields in the device under test and lets him assess which structures are particularly at risk.

Test set-up:

Figure 45 shows the test-set-up for measuring burst-related magnetic fields in the device under test. The SGZ 21 generator outputs are connected to the module. A single-pole or two-pole connection can be used for the set-up. The optical fibre is connected to the rear of the magnetic field probe. Remember that the optical fibre has to be inserted through to the conical socket of the transmitter diode. The transmitter diode is close to the probe's front end. The other end of the optical fibre is connected to the SGZ 21's counter input.

The disturbance current which is fed into the module distributes according to the module's metallic system. The ground system usually accounts for the largest share of the metallic system. This means that the disturbance current will flow via the ground system and the respective magnetic field depends on the form of the ground system. Figure 46 shows the current flow and the respective magnetic field.

If the ground system does not comprise a closed surface but is split by gaps, strong magnetic fields will be generated in these gaps and will have a particularly negative effect on lines which are located there. The MS 02 magnetic field probe can be used to search for these critical points.

6 Safety instructions

When using a product from LANGER EMV Technik GmbH, please observe the following safety instructions to protect yourself from electric shocks or the risk of injuries. The device may only be used by personnel who are qualified in the field of EMC and who are fit to work under the influence of disturbance voltages and (electric and magnetic) burst fields. Read and follow the operating instructions and keep them in a safe place for later consultation.

- Never use any damaged or defective devices.

- Carry out a visual check before using a measurement set-up with a Langer EMV-Technik GmbH product. Replace any damaged connecting cables before starting the product.

- Never leave a Langer EMV-Technik GmbH product unattended whilst this is in operation.

- The Langer EMV-Technik GmbH product may only be used for its intended purpose. Any other use is prohibited.

- Observe the operating and safety instructions for all devices used in the set-up.

- People with a pace-maker are not permitted to work with this device.

- The test set-up should always be operated via a filtered power supply.

Attention! Functional near fields and interference emissions may occur when operating EMC test set-ups. The user is responsible for taking measures to prevent any interference to the correct function of products outside the EMC environment of the test set-up (in particular through radiated interference).

This can be achieved by:

- observing an appropriate safety distance,

- use of shielded or shielding rooms.

- The disturbances that are injected into the ICs can destroy (latch-up) the device under test if their intensity is too high.

Protect the device under test by:

- increasing the disturbance gradually and stopping when a functional fault occurs,

- interrupting the power supply to the device under test in the event of a latch-up.

Attention! Make sure that internal functional faults are visible from outside. The device under test may be destroyed due to an increase in the injection intensity if the faults are not visible outside. Take the following measures as necessary:

- monitoring of representative signals in the device under test,

- special test software,

- visible reaction of the device under test to inputs (reaction test of the device under test).

We cannot assume any liability for the destruction of devices under test!

7 Warranty

Langer EMV-Technik GmbH will remedy any fault due to defective material or defective manufacture, either by repair or by delivery of replacement, during the statutory warranty period.

This warranty is only granted on condition that:

- the information and instructions in the user manual have been observed.

The warranty will be forfeited if:

- an unauthorized repair is performed on the product,

- the product is modified,

- the product is not used according to its intended purpose.

8 Technical specifications

| SGZ 21 pulse density / burst generator | ||

| Dimensions | WxDxH | (154x100x62) mm |

| Pulse parameters | Rise time: | approx. 2 ns |

| Tail time: | approx. 10 ns | |

| Peak values: | approx. 0...1500 V evenly distributed | |

| Pulse interval: | approx. 1 ms | |

| Output | symmetric, galvanically isolated | |

| Contact gap | mechanical spark gap | |

| Counter | Display: | 6-digit (1 MHz) |

| Peak time: | 1 s | |

| Optical input | max. frequency: | 5 MHz |

| Minimum pulse width: | 100 ns | |

| Optical fibre: | 2.2 mm plastic | |

| Power supply unit | 12 Volt | 200 mA | |

| Standards used as a basis for CE mark test | Emission: | EN 50 081-1 /-2 |

| Immunity: | EN 50 082-1 /-2 | |

9 Scope of delivery

10 Optional components

10.1 S2 magnetic field probe set

The probes in the S2 set have a significantly higher resolution than the MS 02. The set also comprises three different exchangeable probe heads which can be used for different tasks (Figure 49) such as measuring pin-related magnetic fields and disturbance currents on ICs and on individual conductor runs (Figure 48).

10.2 Digital or analog optical signal transmission

Analog and digital signals can be transmitted from the device under test to an oscilloscope with special optical sensors. This transmission is without interaction. The benefit of these systems is that signals of the device under test can be recorded with an oscilloscope under the influence of disturbances (Figure 50).

This document may not be copied, reproduced or electronically processed, either in its entirety or in part, without the prior written permission of Langer EMV-Technik GmbH. The management of Langer EMV-Technik GmbH assumes no liability for damage that may arise from using this printed information.